2012 Annual Science Report

NASA Jet Propulsion Laboratory - Titan

Reporting | SEP 2011 – AUG 2012

NASA Jet Propulsion Laboratory - Titan

Reporting | SEP 2011 – AUG 2012

Task 1.2 Interaction of Methane/ethane With Water Ice

Project Summary

A Titan lake simulation system is under construction to provide a testbed for testing small instruments and components at Titan lake conditions in preparation for future in-situ missions.

Project Progress

Colleague Mathieu Choukroun, working with Co-Investigator Pat Beauchamp, initiated the development of a Titan Lake Simulation System (TiLSS) at JPL. The TiLSS consists of an existing, large (24” ID x 26” height), high-vacuum cryogenic chamber in which a high-pressure vessel of 10 L internal volume is nested. The purpose of this system is to provide a testbed for testing small instruments and components at Titan lake conditions in preparation for future in-situ missions to Titan. In addition, this system provides a relatively large and controlled environment for scientific experiments. In particular, a SRI gas chromatograph with a flame-ionization detector and methanizer is connected to both the liquid and the gas head space, allowing for precise determination of the composition of liquids with a Titan-like atmosphere (1.5 bar N2, vapor pressure of hydrocarbons).

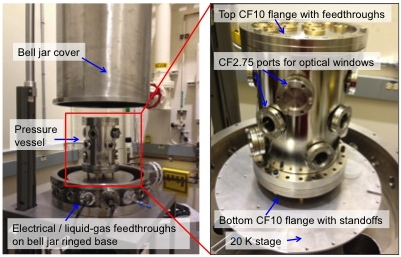

Figure 1 shows the core component of the TiLSS: a high-pressure chamber, custom built by MKS Instruments, with 12 sapphire windows of design pressure 1000 psi for optical viewing. The pressure vessel is conductively cooled via brass posts that connect it to a temperature-controlled aluminum plate cooled by a closed-cycle He cryostat. The vacuum chamber achieves a pressure of 10-5 to 10-6 mbar, and the He cryostat provides cooling to 30 K. Temperature in the vessel is achieved by resistive heating, and thermal gradients are minimized by shrouds with space-flight-grade multi-layer insulation.

Significant infrastructure modifications have been achieved over the past year: gas storage, mixing, and delivery systems have been developed and installed, including piping through the building walls; the safety hazards associated with this system required a detailed safety analysis and complex design, including an automated gate valve for the turbo-molecular pump as well as the purchase of custom-designed burst disks, and modifications of the system to ensure safe operation at all time. All main components have been purchased and received, and the system is presently undergoing final assembly.

Figure 1. Photograph and description of the core component of the TiLSS.

-

PROJECT INVESTIGATORS:

-

PROJECT MEMBERS:

Patricia Beauchamp

Co-Investigator

-

RELATED OBJECTIVES:

Objective 2.2

Outer Solar System exploration

Objective 3.1

Sources of prebiotic materials and catalysts